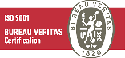

A growing number of research teams are turning their attention to kesterite solar cells (Cu₂ZnSn(S,Se)₄) — commonly referred to as CZTS or CZTSSe in the search for sustainable, earth-abundant materials for next-generation photovoltaics. As thin-film solar devices continue to evolve, kesterites stand out for their low toxicity, affordable raw materials, and compatibility with vacuum-based deposition techniques.

Like their CIGS (Copper Indium Gallium Selenide) cousins, kesterite cells adopt a similar crystal structure and manufacturing approach, but replace indium and gallium with zinc and tin, two elements that are far more abundant and significantly cheaper. This shift not only reduces cost but also addresses concerns over the critical material supply chain for solar production.

Recent progress in CZTSSe research has focused on improving power conversion efficiency (PCE), with the most advanced prototypes now reaching 12–13%, up from just 6–7% a decade ago. These improvements are due to better stoichiometric control during deposition, more stable interfaces, and novel passivation techniques using materials like ZnO, CdS, and ALD-grown buffer layers.

Key research teams in Germany, Japan, and India have reported success using co-evaporation, sputtering + annealing, and hybrid PVD-sulfurization approaches. In many of these processes, kesterite films are grown in controlled atmospheres, often within glove boxes, then heat-treated in sulfur or selenium to optimize grain growth and absorber properties.

One major breakthrough came with the introduction of ALD (Atomic Layer Deposition) for ultrathin interface layers, which dramatically reduced recombination at the CZTSSe/buffer junction. This technique, already widely used in perovskite and OLED research, shows promise for further improving efficiency and long-term stability.

In terms of applications, kesterite solar cells offer several advantages:

- Non-toxic and environmentally safe (cadmium-free versions are in development)

- Cost-effective materials and processing

- Thin, flexible and lightweight, suitable for building-integrated photovoltaics, rural electrification, and off-grid systems

- Compatible with existing PVD, sputtering, and glove box infrastructure

PhotonExport supports CZTS development through the supply of:

- Vacuum deposition systems (PVD, ALD, sputtering)

- Process-compatible glove boxes

- Sputtering targets, TCOs, and evaporation materials

While kesterites still trail perovskites and CIGS in efficiency, they represent an increasingly viable solution for sustainable solar cell production. As process control improves and new fabrication strategies emerge, CZTS is expected to play a growing role in the global transition toward low-impact, scalable photovoltaics.

“The real value of kesterite lies not just in performance, but in accessibility,” said Dr. María González, materials scientist at CIEMAT. “It’s a technology designed for global deployment — where cost, abundance, and sustainability matter most.”

As researchers refine CZTS architectures and overcome bottlenecks in carrier transport and defect density, kesterite may soon join perovskite as a key player in next-generation solar cell innovation.